ECG HMI - Complete Electrocardiographic Device

Overview

Design and realization of an integrated portable ECG device, combining cleanroom microfabrication, embedded electronics, and display interface. Multidisciplinary project covering the entire biomedical measurement chain: from sensors to real-time visualization.

Objectives

Develop a functional electrocardiogram prototype integrating:

- Custom-fabricated ECG electrodes in cleanroom

- Acquisition card for signal processing

- Display interface (OLED/LED matrix)

Technologies Used

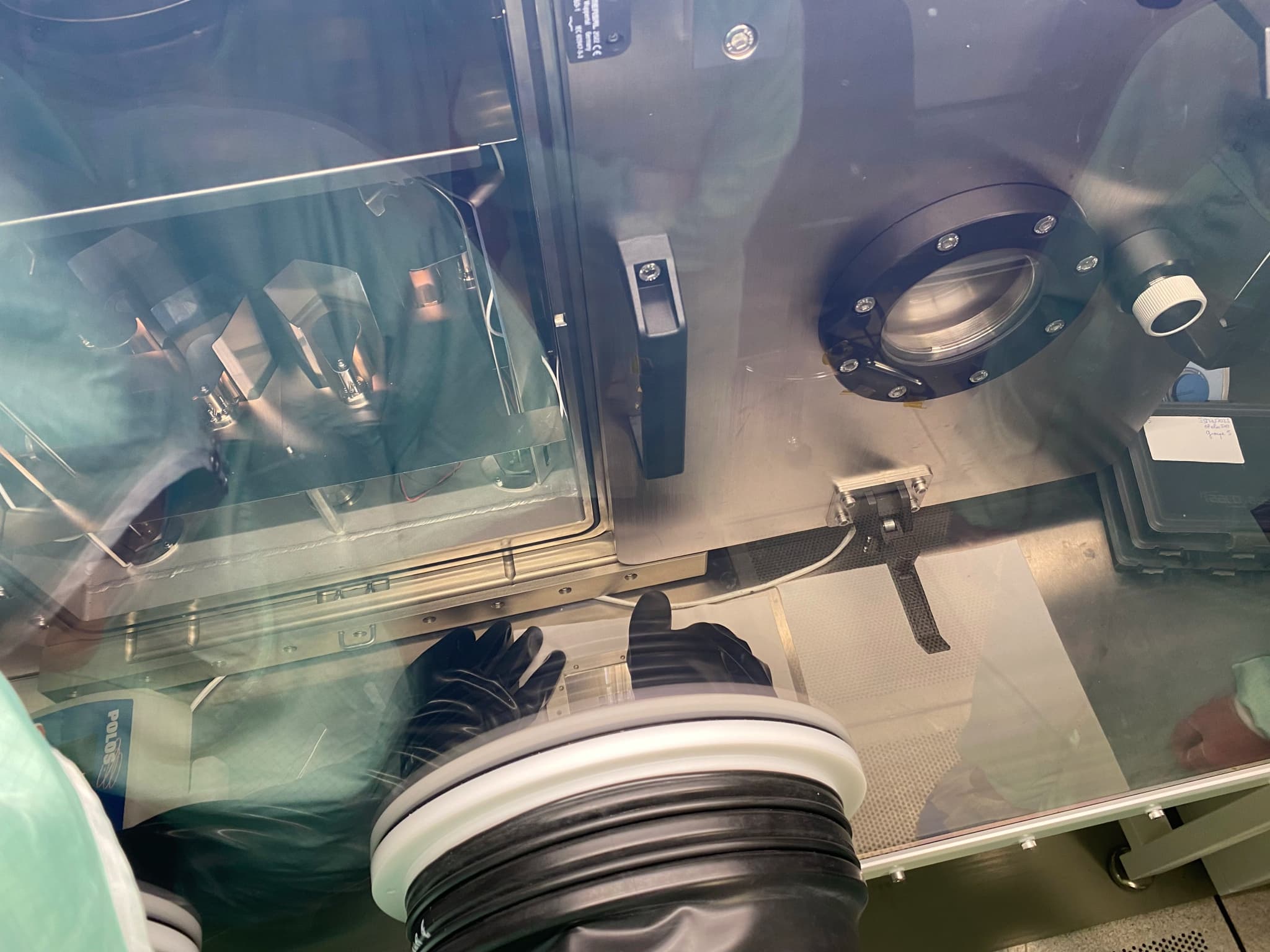

Microfabrication

- Photolithography: Electrode structuring

- Vacuum evaporation: Ti/Au and organic layer deposition

- PEDOT:PSS: Conductive polymer for impedance improvement

- Kapton (polyimide): Flexible substrate for electrodes

Electronics & Programming

- STM32: Microcontroller for signal processing

- CMSIS-DSP: Library for FIR filtering

- UART: Serial communication for visualization

- PCB fabrication (SMD components, reflow)

Characterization

- Impedance spectroscopy: Electrode performance measurement

- Ellipsometry: Layer thickness control

- Oscilloscope: ECG signal validation

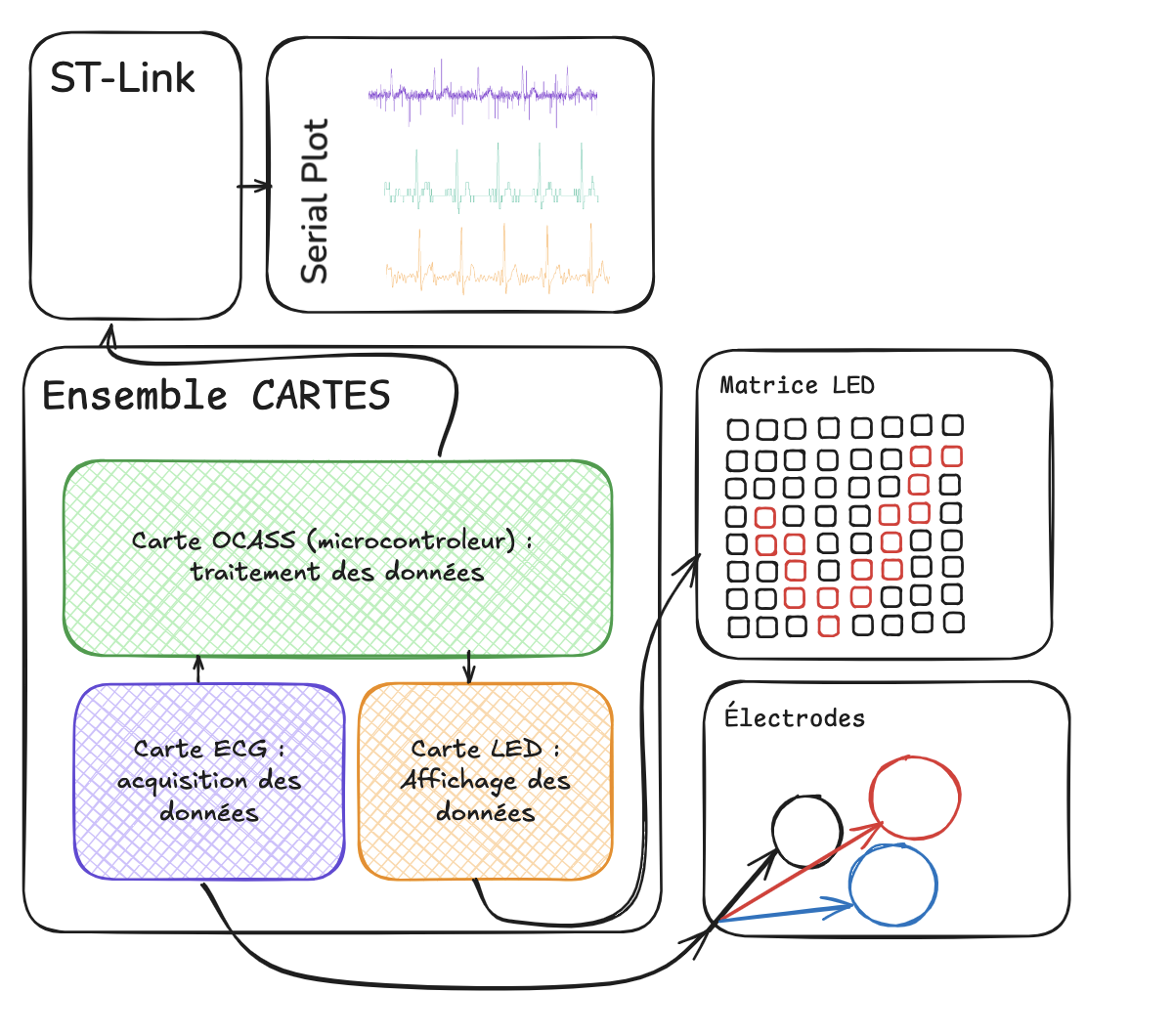

System Architecture

1. ECG Electrodes (Cleanroom)

Fabrication process:

- Flexible Kapton substrate

- O₂ plasma treatment for activation

- Photolithography (S1813 photoresist)

- Ti/Au evaporation (100nm)

- Lift-off and cleaning

- PEDOT:PSS coating

Performance:

- Impedance ~7 Ω (comparable to commercial electrodes)

- Water-only operation (no conductive gel)

- Nyquist diagram compliant

2. ECG Acquisition Card

Fabrication:

- SMD components soldered by reflow (stencil + hot plate)

- ±15V power supply

- Test points for validation

Signal processing:

- ECG signal capture via electrodes

- FIR filtering (CMSIS-DSP)

- UART transmission to Serial Plot

- Real-time visualization

3. Display Matrix

OLED attempt:

- Multilayer architecture (ITO/HTL/EML/ETL/Al)

- Thermal and co-evaporation

- Real-time thickness monitoring (Inficon)

- Nitrogen encapsulation

Alternative solution - 8×8 LED Matrix:

- Multiplexing card fabricated

- Adapted programming (eCampus library)

- Functional scrolling text display

Technical Challenges

Microfabrication

- Control of deposition uniformity

- Environmental management (oxygen, humidity)

- Lift-off process precision

Electronics

- SMD component soldering (defective vias)

- Methodical debugging of multiplexing card

- Multi-filter processing stability

OLED

- Oxygen spike during chamber opening (machine fault)

- Missing HBL layer → excessive voltages (13-20V)

- Matrix non-functional outside neutral environment

Learnings

Technical Skills

- Mastery of cleanroom techniques (photolithography, evaporation)

- Optical and electrical component characterization

- Real-time biomedical signal processing

- Electronic circuit fabrication and debugging

Methodology

- Importance of scientific rigor (impact of attention errors)

- Systematic and methodical debugging

- Adaptation to hardware constraints

- Multidisciplinary integration (chemistry, physics, electronics, computer science)

Innovation

- Development of gel-free biomedical electrodes

- Complete portable medical device architecture

- Mastery of complete chain: sensor → processing → display