IoT Connected Greenhouse - Smart Agriculture

Overview

Design and realization of a connected greenhouse using IoT technologies to optimize agricultural growing conditions while minimizing resource consumption. Complete system integrating environmental sensors, LoRaWAN transmission, cloud visualization, and actuator automation.

Context & Problem Statement

Environmental Challenges

Agriculture is on the front line of climate change, facing major challenges:

- Carbon impact: 10-12% of human-caused GHG emissions

- Water scarcity and increasingly harsh climate conditions

- Need to optimize resources (heating, irrigation) while maintaining productivity

Problem Statement

How to use IoT technologies to improve agricultural productivity in greenhouses while optimizing resource usage?

Objectives

Develop a functional prototype to:

- Monitor greenhouse environmental conditions in real-time

- Transmit data to a cloud platform for analysis

- Automate actuators (heating, ventilation, irrigation) based on actual needs

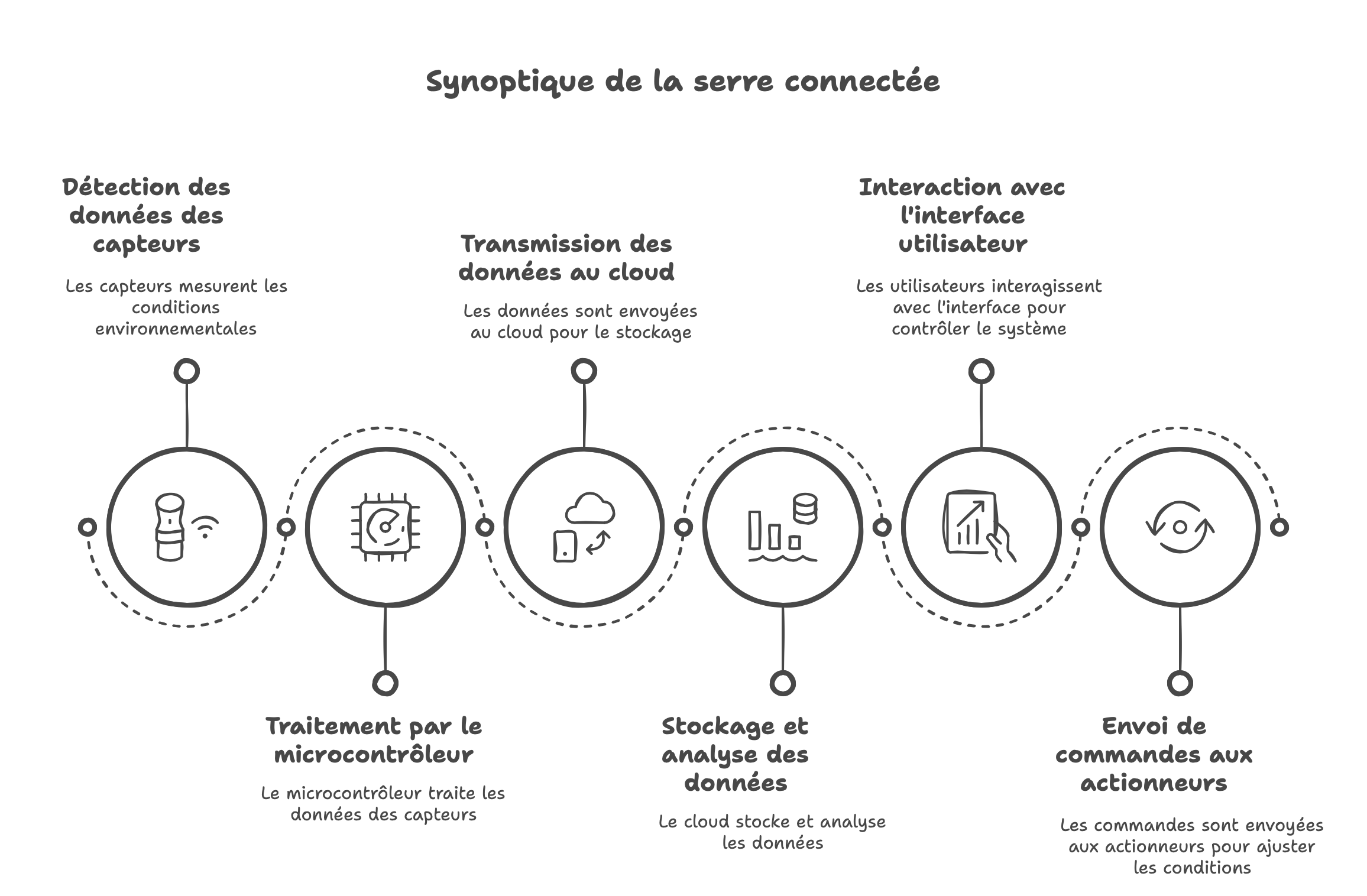

System Architecture

1. Environmental Sensors

BME680 (I2C):

- Temperature

- Air humidity

- Atmospheric pressure

- Air quality (IAQ)

LM94021 (ADC):

- Temperature (reference sensor selected for stability)

2. Microcontroller

OCASS Board:

- Data collection every 15 seconds (Timer 6)

- Signal processing and conditioning

- Actuator control via downlinks

- Embedded C programming

Interfaces used:

- ADC for LM94021

- I2C for BME680

- LoRaWAN for wireless transmission

3. LoRaWAN Transmission

Technical Choice:

- Range: ~10 km in rural environment

- Low energy consumption

- Reasonable cost

- The Things Network (TTN) for reception

Alternatives studied:

- WiFi rejected: limited range (~10m), high consumption, interference-sensitive

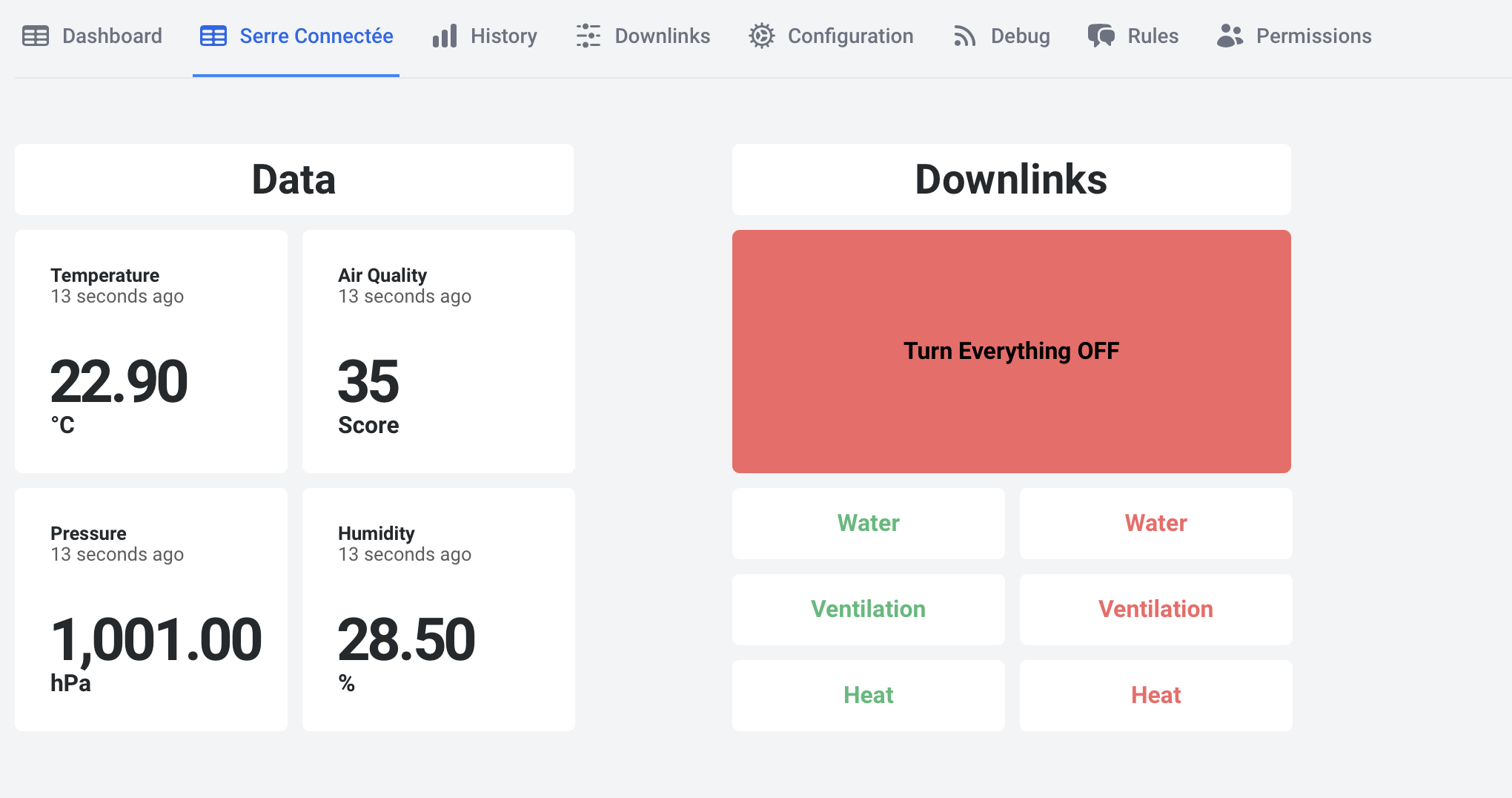

4. Cloud Platform - Datacake

Two developed dashboards:

Simplified dashboard:

- Quick visualization of essential data

- Manual actuator control buttons

- Fast actions in emergency

Complete dashboard:

- Historical graphs for trend analysis

- All environmental metrics

- Automation rules configuration

5. Automation & Actuators

Automated actions (Datacake Rules):

- Heating: Activation if temperature < threshold

- Ventilation: Trigger if poor air quality

- Irrigation: Activation if humidity too low

- SMS Alerts: Notifications for critical conditions

Manual controls:

- Individual buttons per actuator

- Emergency button for global shutdown

Testing & Validation

2-Phase Test Protocol

Phase 1 - LM94021 only:

- General operation validation with USART available

- Comparison of sent vs received data

- Downlink testing with indicator LED

- ✅ Transmission and reception validated

Phase 2 - BME680 Integration:

- I2C communication (replaces USART)

- Data consistency validation on platform

- Multi-parameter display verification

- ✅ All metrics operational

Results Obtained

Temperature sensors:

- LM94021: Stable, reliable, selected as reference

- BME680: Variations up to 3°C between measurements, constant 1°C offset

- → Decision: Use LM94021 for temperature

Other BME680 parameters:

- ✅ Humidity: Accurate and consistent

- ✅ Atmospheric pressure: Reliable

- ✅ Air quality: Usable for ventilation control

Automation:

- ✅ Downlinks received and processed correctly

- ✅ Actions triggered according to configured rules

- ✅ LED test validated (actuator proof of concept)

Impact & Optimization

Resource Savings

Reactive and adaptive system:

- Heating activated only when necessary

- Irrigation triggered based on actual needs (no waste)

- Ventilation optimized according to air quality

- → Significant reduction in water and energy consumption

Optimal Growing Conditions

- Continuous 24/7 monitoring

- Reactivity to environmental variations

- Historical data for analysis and predictions

- Alerts for critical conditions

Future Prospects

Technical Extensions

- Additional sensors: Soil moisture, sunlight, CO₂

- Artificial intelligence: Weather predictions and plant needs

- Field testing: Validation in real production conditions

Extended Applications

- Underground urban mushroom farms

- Urban green space management

- Specialized crops (aromatic herbs, microgreens)

Technologies Used

Hardware: BME680, LM94021, OCASS board, actuators (relays)

Communication: LoRaWAN (868 MHz), The Things Network (TTN), I2C, ADC, UART

Programming: Embedded C, LoRaWAN configuration

Cloud: Datacake (dashboards, alerts, API)

Skills Developed

- Embedded systems (C, timers, ADC, I2C, UART)

- IoT protocols (LoRaWAN, ABP, duty cycle management)

- Cloud architecture (TTN, Datacake, API)

- Environmental sensors and calibration

- Remote automation and control

- Energy optimization for autonomous systems